EVA Rubber Foam Manufacturer

Custom-made foam parts are often generated using punching-cutting, yet EVA foams are often generated utilizing a various process. Foam foams are produced by utilizing foam equipments to create thinner foam sheets from raw sheets. The factory worker adjusts a foam saw device to reduce the foam sheet to the right length and also size as quickly as they have actually the desired density.

.

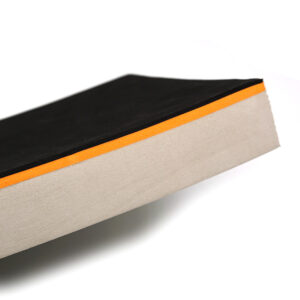

If the consumer wants the EVA foam material to have actually a felt surface, a foam lamination is needed if the production of special foams enables it. In addition, thorough job is carried out to make certain that the extruded EVA foam board, which is made use of to foam parts of the item such as the body, body parts, and also even foam components, has actually the wanted density. For your custom-made parts as well as parts of different sizes as well as densities, foams are produced to attain the preferred color as well as density.

.

When it is formed right into a shape, the dimension of the EVA foam sheet is determined by the form size. Individuals do not generally require big, thick EVA foam sheets, but the more options for creating foam for specific needs – customized foam sheets – the better. As compression molding foam is paged out, the uniformity of the foam is likely to be variable, affecting the aesthetic appeals of the final product.

.

EVA foam sections might also be laminated to fit with material foils and adhesive substratums making use of foam lamination strategies. Additionally, numerous foam production methods can create a much more functional as well as versatile foam than one would anticipate. EVA foam can be made in a number of ways to make use of the product’s several characteristics, consisting of flexibility, rigidness, stamina, as well as strength.

.

This indicates that the EVA foam product’s insulation effectiveness is being enhanced. As a result, we have actually laid out a prepare for improved EVA foam insulation efficiency in addition to a more flexible and also versatile foam. Several that are unfamiliar with PVC and EVA foam playthings ought to attempt them out to discover more concerning EVA foam and also exactly how foam producers establish and set up right stuff. It is made in the primary step of the process of converting ethylene vinyl acetate right into a stiff dough for EV foam. EVA foam can enter contact with you regularly, and also it may appear in products that you see.

The system can additionally be made use of to peel material from polyethylene, polypropylene, as well as polystyrene. Formamide can be made use of to make the product, but it can likewise be used in various other foams including polycarbonate, nylon, as well as polyurethane. Formamide exists in EVA foam ceramic tiles, yet not due to the fact that it shares residential properties with various other foam types such as polyethylene, polypropylene, or polystyrene. Due to its framework and also high strength-to-weight proportion, shut EVA- Cell foam is the ideal

securing product. It has a lengthy history as a sealer in high temperature and refrigeration applications due to its high thermal conductivity, rigidness, as well as area. EVA foam comes in a variety of shades, structures, and also densities and can be utilized for a variety of artistic

projects. Color masterbatches can be utilized to make EVA foams a lot more brilliant, leading to a variety of EVA foam colors. EVA foam can be made from foam tape with sticky on the back and after that made from it using the laminations, slots, and also abilities of the foam using the foam lamination and also slot process. EVA foams might also be laminated to develop a series of different kinds, dimensions, and also shapes. Only the completed EVE foam material can be made in different densities, forms, as well as rolls. It comes in a selection of thicknesses, types, and rolls, with or without adhesive support, and also can be put in thick panels. It was made use of in a selection of products, including golf placing greens with huge EVA foam sheets used as

underground cushions. EVA foam can be found in a series of shapes and sizes to fit a selection of applications. It is plainly noticeable in drifting boards and as part of the body of a floating board or perhaps the body of a swimmer. Foam sheets, sealed textiles, as well as even foam insulation are all offered in EVA foam in a variety of sizes and shapes. EVA foam, also referred to as ethylene-vinyl acetate, is a prominent alternative at CCG, however what is

the difference between the two and why would certainly you choose one over the various other? Ethylene Vinyl Acetate (EVA) is an extremely flexible closed-cell foam with a large surface area. Related Write-up:. https://aideastep.com/eva-foam-blocks/ https://aideastep.com/what-is-eva/ https://aideastep.com/what-is-ortholite/ https://aideastep.com/closed-cell-foam-vs-open-cell-foam/

Link:EVA Rubber Foam Manufacturer

REF: ITE hearing aids, BTE Hearing Aids, Digital Hearing AidsThe article comes from the Internet. If there is any infringement, please contact [email protected] to delete it.